A new spin on thin films

Posted by magazine

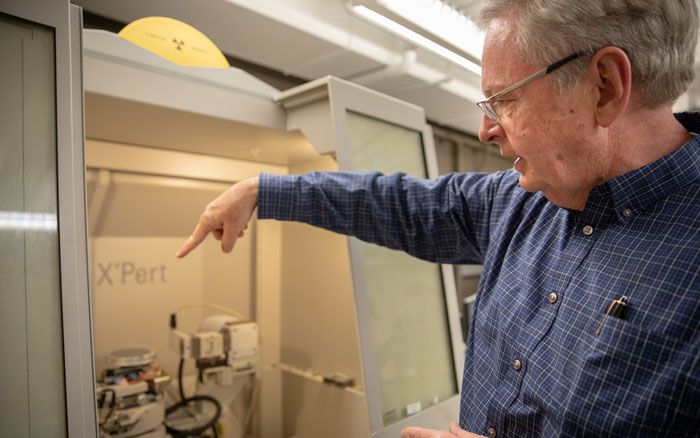

Jay Switzer explains the spin coating process used to produce epitaxial films and nanocrystals. His research was published in “Science” in April.

You could say Jay A. Switzer is a spin doctor of sorts. The materials scientist and his research team have devised a way to create high-performance inorganic thin films. Also known as epitaxial films, they are used in the manufacture of semiconductors.

“We’ve come up with a super-easy method that has never been done before to make these films from a solution using commercial spin coaters,” says Switzer, the Donald L. Castleman/Foundation for Chemical Research Professor of Discovery in Chemistry at Missouri S&T. “This is an inexpensive and readily accessible route to single-crystal-like materials that should exhibit superior electronic and optical properties.”

He and his team published their research in Science in April.

Switzer’s work uses epitaxial deposits of cesium lead bromide, a semiconductor used in highly efficient photovoltaic solar cells.

Epitaxy is the growth of crystals, or thin films, whose orientation is determined by the crystalline substrate they are layered on. When the atomic structure of these crystals perfectly aligns with their substrate, the result is a film with superior electronic and optical properties that rival the attributes of more expensive single crystals.

Until now, spin coating has been used primarily to make lithographic polymer coatings or to deposit organic semiconductor films on substrates. But the resulting films have been either polycrystalline or without crystalline structure — not epitaxial with the level of perfection needed for today’s state-of-the-art electronics.

“We’ve learned to use spin coating to make highly oriented films and nanocrystals on a variety of inorganic substrates,” says Switzer. “Until now, atomically perfect epitaxial films have been made by several other methods, and some of those are very expensive and require ultra-high vacuum.”

Over two years, the research team showed that epitaxial films of inorganic materials such as lead iodide, zinc oxide, sodium chloride and perovskite crystal structures could be deposited on single crystals or comparable substrates by simply spin-coating their solutions or precursors of the materials.