Crushing it for science

Posted by Lindsay Stanford

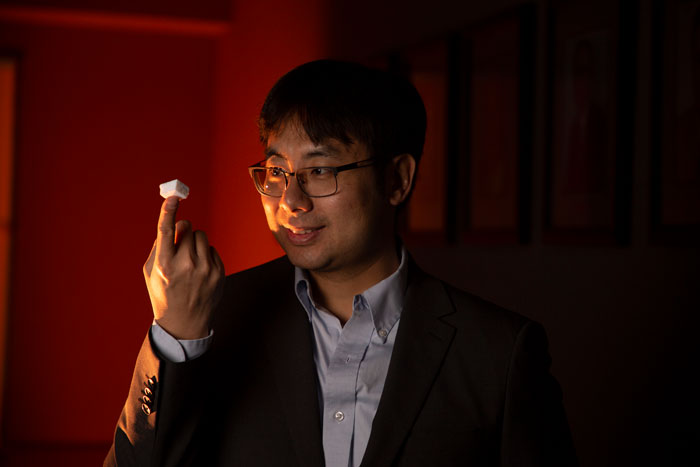

Dr. Chenglin Wu investigates the mechanical properties of aerogels at the nanoparticle level – combining experiments and computer modeling to look at how polymeric aerogels can fail and become deformed. By crushing and indenting aerogels, they gained a better grasp on the gels’ properties.

Want to build a better aerogel? You need to start by crushing them, say S&T researchers. Their findings were first published in August 2018 in Soft Matter, a Royal Society of Chemistry journal that focuses on the intersection of physics, chemistry and biology.

Aerogels are a diverse class of solid materials derived from a gel in which the liquid component of the gel is replaced with gas, making them lightweight and strong. The strong, flexible and ultralight materials are used in a wide variety of products, from insulation for offshore oil pipelines to parts for space missions. By crushing and indenting aerogels, S&T researchers have gained a better grasp on the gels’ mechanical properties at the nanoparticle level and can provide insights into how polymeric aerogels can fail and become deformed.

“We looked at the deformation of polyurea aerogels at a very small scale — at the building blocks themselves,” says Chenglin Wu, assistant professor of civil, architectural and environmental engineering at Missouri S&T. “The data that we have obtained has provided, for the first time, first-hand information on nano-deformation of nanoporous polymers, and will be useful in the design, optimization and engineering of polymeric aerogel and soft nanoporous materials.”

Wu and his team identified four failure modes of aerogel structures. They found that material scaling properties depended on both the relative density and the secondary particle size of the gels. That means there is not a conventional power-law relationship between the aerogels.

“Our research could be applied to areas such as energy absorption in ballistic protection to biomedical implants and drug-delivery platforms,” says Wu. “This work enables the rational nanoscale-up design of nanoporous polymers for a very wide spectrum of applications ranging from ballistics to biomedicine to space exploration.”