Dissolving electronics

Posted by magazine

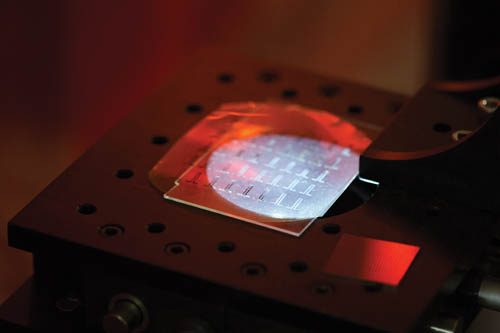

Mechanical and Aerospace Engineering department professor Heng Pan is conducting research into dissolving bioresorbable electronics. October 20, 2017. Jesse Cureton / Missouri S&T

Electronic devices that can not only be implanted in the human body but also completely dissolve on their own — known as “bioresorbable” electronics — are one of medical technology’s next frontiers.

In a study published in the journal Advanced Materials, S&T researcher Heng Pan shows that a laser printing technique using nanoparticles could lead to a more cost-effective approach to building sturdier and safer components.

Pan, an assistant professor of mechanical and aerospace engineering, is working with Xian Huang, a professor of biomedical engineering at Tianjin University in China, to use lasers to process print-ready zinc nanoparticles, then uses them to print tiny electronic components.

Pan says bioresorbable electronics (or transient electronics) that use traditional microchip fabrication methods require expensive optical patterning and vacuum deposition processes. Laser printing is far more cost-effective — but could cause adverse interactions.

The new process sinters zinc nanoparticles together through an evaporation and condensation process that avoids surface oxides. The fabricated, oxide-free zinc conductors showed high electrical conductivity, were more durable and dissolved better in water.

Co-authors with Pan and Huang are Missouri S&T mechanical engineering Ph.D. students Xiaowei Yu, Wan Shou, Brandon Ludwig and Joshua Staggs, and Bikram K. Mahajan, a master’s student in mechanical engineering at S&T.