Rubber cement?

Posted by Mindy Limback

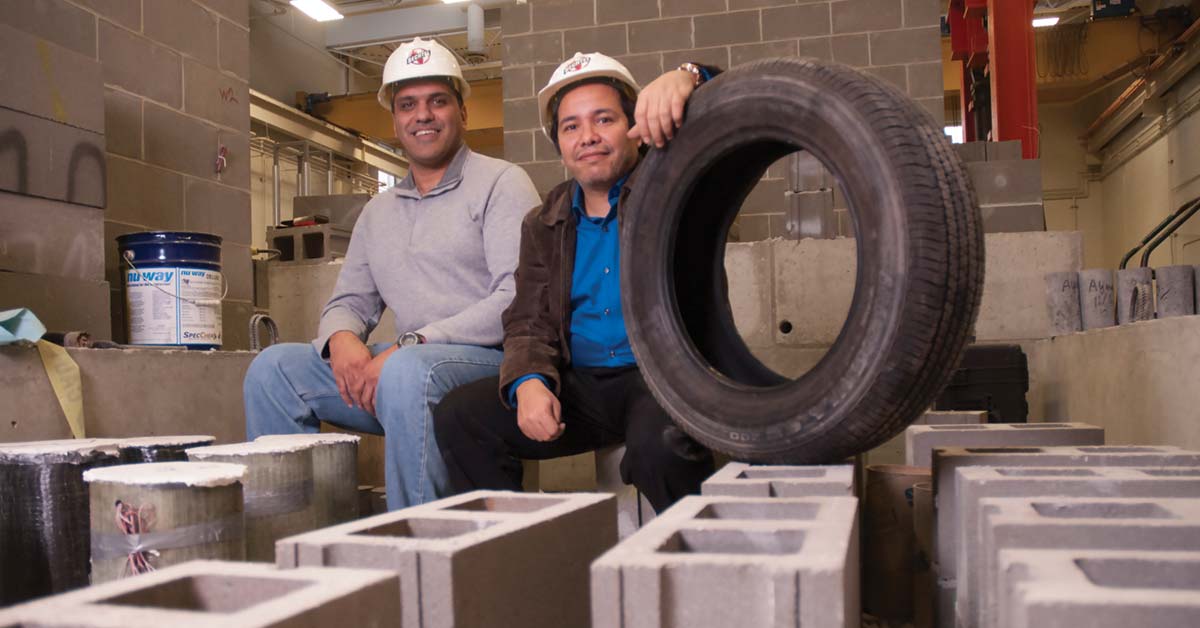

Mohamed A. ElGawady, right, and graduate student Ahmed Gheni are recycling old tires to make masonry blocks. Photo by B.A. Rupert

Landfills across the country are teeming with discarded tires. But Mohamed A. ElGawady, an associate professor of civil, architectural and environmental engineering, says he can solve that problem by turning them into an ingredient for construction materials.

ElGawady is working with Midwest Block and Brick in Jefferson City, Mo., to use ground tires in masonry blocks. He says tires’ longevity and resilience make them ideal for the project.

“Rubber has a lot of benefits in addition to its sustainability,” he says. “It’s very durable and provides good insulation. Among their many potential benefits, these new blocks could cut heating bills by 50 percent.”

ElGawady tested blocks with varying percentages of rubber until he found the right combination. Replacing 20 percent of the sand in concrete with rubber allows the blocks to retain their strength.

He and his students use a compression machine to test and compare the strength of structures built with the rubberized blocks to conventional concrete masonry blocks.

They are testing both rubberized and conventional blocks in an environmental chamber, where they undergo cycles of extreme temperatures and humidity levels that simulate different weather conditions. The rubberized blocks are also tested under cyclic compression loads that simulate an earthquake.

“Construction with these new blocks could improve a building’s resiliency during an earthquake by acting as shock absorbers,” ElGawady says.