Blue gem, greener fuel

Posted by magazine

Sapphire, a brilliant blue gemstone most familiar in jewelry, may soon play an important part in making coal a cleaner fuel source.

Missouri S&T researchers are investigating sapphire’s suitability as sensors that could survive the harsh, hot environment of coal-gasification plants. These plants produce synthesis gas (syngas), a synthetic form of natural gas that can be used for power generation and transportation.

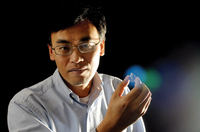

Hai Xiao says sapphires can take the heat when it comes to making clean coal.

Sapphire is also a tough mineral and, when grown as single-crystal sapphire, is able to withstand extreme temperatures. That’s why the Missouri S&T researchers think it could handle the heat of coal gasification.

“It’s a very harsh environment,” Hai Xiao, associate professor of electrical and computer engineering at Missouri S&T, says of the systems that turn coal into syngas. Those environments also require precise temperature and pressure controls to make syngas as cleanly as possible.

“The high temperature ensures the efficient transformation of coal to syngas, creating less waste and sustaining a better environment,” Xiao says.

One roadblock to the coal gasification technology is the lack of process control instrumentation that can handle the harsh environment. “There’s a huge technology gap for sensing and monitoring in harsh environments in general,” Xiao says.

Xiao and his colleagues believe sapphire can take the heat. But they still have to figure out how to turn the crystal into a sensor that is only about 100 microns in diameter — about the thickness of a human hair. The sensors will take the form of fibers.

The researchers’ first task is to design and build the sensors with the ability to measure temperature as well as gas pressure. If laboratory tests prove successful, they will then explore the possibility of testing the sensors in actual production facilities, working with AmerenUE, a utility company based in St. Louis, to field-test the sensors.

The three-year research project began last October and is funded by the U.S. Department of Energy National Energy Technology Laboratory. Working with Xiao on the project are H.L. Tsai, professor of mechanical and aerospace engineering at Missouri S&T, and Junhang Dong, associate professor of chemical and materials engineering at the University of Cincinnati. AmerenUE staff are assisting the researchers.