Prime slime: UMR has big plans for underground algae

Posted by

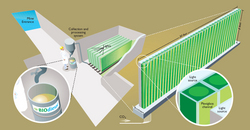

Imagine thousands of Plexiglass tubes stored underground much like wine in a temperature-controlled cellar. While grapes are the prime ingredient in a bottle of Chardonnay, these tubes are full of odorous algae. And the long tubes of green slime are stored vertically, with carbon dioxide bubbling up from the bottom. Timed pulses of water push overflow algae – engineered to replicate four times daily – out the top of the tube and into a collection system, where the overflow is squeezed to yield, get this, crude oil.

Imagine thousands of Plexiglass tubes stored underground much like wine in a temperature-controlled cellar. While grapes are the prime ingredient in a bottle of Chardonnay, these tubes are full of odorous algae. And the long tubes of green slime are stored vertically, with carbon dioxide bubbling up from the bottom. Timed pulses of water push overflow algae – engineered to replicate four times daily – out the top of the tube and into a collection system, where the overflow is squeezed to yield, get this, crude oil.

“Why wait 10 million years for oil?” asks David Summers, one of the masterminds behind UMR’s underground algae project.

Typical algae are about 25 percent oil, which gives the slimy stuff its floating properties. The key to making UMR’s plan work is maintaining constant reproduction rates and finding a way to extract the oil efficiently.

Researchers have long known about the possibilities of extracting oil from algae and various crops. A lot of money has been put into producing biofuels from corn and soybeans, for instance. But, according to Summers, there is a growing conflict between using the crops for food or fuel – and the process of growing the crops, alone, consumes energy, time and space.

Algae, if we think of it as a crop, is capable of producing significantly more transportation fuel than corn or soybeans. And researchers have already discovered that, because the algae eat carbon dioxide, they thrive when cultivated in water near coal plants. But would it be worthwhile to grow algae around every coal plant in the country?

Surface cultivation means high evaporation rates in warm weather and slow growth in cool weather. Algae are also vulnerable to being swamped by domestic species. “So the light goes on, because I’m a coal miner,” says Summers, Curator’s Professor of mining engineering. “Why not try this underground?”

The fact that algae feed on carbon dioxide makes an underground coal mine – like UMR’s Experimental Mine – the perfect incubator. According to Summers, the United States has a lot of unused space underground. “In underground coal mines, temperatures are easy to keep constant,” he says, “even at the higher temperatures that algae prefer.”

Summers also realized that, under the surface, the algae would not be vulnerable to infestation and could be grown in three dimensions. “Soybeans and other crops grow on the surface in two dimensions,” Summers says, flattening his hand in the air to illustrate a point about volume. “Algae isn’t a scarce resource, by any means. It breeds so rapidly under the right conditions – you could fill a whole mine eventually from one vial. And algae don’t really need all of the light that comes from the sun. If the electrical engineers can provide a good source of light underground, you’ve solved some big problems.”

The algae epiphany is a bit of a departure for Summers, who is best known for his pioneering work with waterjet technology. He sees the new project as a group effort involving many people on campus, including mining engineers, electrical engineers, petroleum engineers, biological scientists, chemical engineers and, of course, students. “We already have experts in many of the disciplines needed, and this project teaches across the spectrum,” Summers says. “We can make this an effort where we bring people to the table to commonly work on the opportunities associated with growing algae underground.”

There are thousands of forms of algae. The best species for this task, according to Dev Niyogi, assistant professor of biological sciences at UMR, would be one with a high growth rate and high oil content. The species would also need to lend itself to culturing, maintenance and harvesting. “We plan to test a variety of local algae from ponds and reservoirs in Missouri to see which ones are most suitable,” says Niyogi. “We anticipate that no species will have all of the best traits, so we will probably maintain several species as good choices for our project. Also, a research group at the National Renewable Energy Laboratory conducted a long study related to this topic and has already identified a set of algal species with desirable traits.”

Even though there is potential for a quantum leap when it comes to thinking about algae as an energy source, Summers and his developing team are taking a conservative approach with respect to the initial steps UMR will take in leading the way. “If we can make a barrel of oil per month the first time around, fantastic,” Summers says. “We’ll then begin to improve. Our graduates will apply their classroom knowledge to real-world problems. Each year, students will have access to all of the earlier data and will be challenged to improve. It’s an ongoing experiment – you’ll see the evolution of this project. We’ll eventually be making significant amounts of oil every day.”

By year five, Summers thinks UMR could have a project that could be taken to a larger mine. Beyond that, he sees investors eventually renting space for underground algae cultivation. These entrepreneurs could sell the extra oil they produce, even in relatively small quantities, to make a profit. The mine owners would make money, too, by leasing the unused space.

Of course, big oil companies would also be interested in underground algae mining operations and the technology used to make them viable. Tests in Mexico have already shown that above-ground algae farms are capable of producing 3,500 barrels of oil per acre. That’s just scratching the surface, as far as Summers is concerned. “

Algae normally runs up to 27 percent oil,” Summers says. “But if you stress them, you can increase the amount to almost 50 percent. If it works, that’s doubling your production. A few years from now, this could be the next big thing. This research could be of critical value to the nation and the world.”